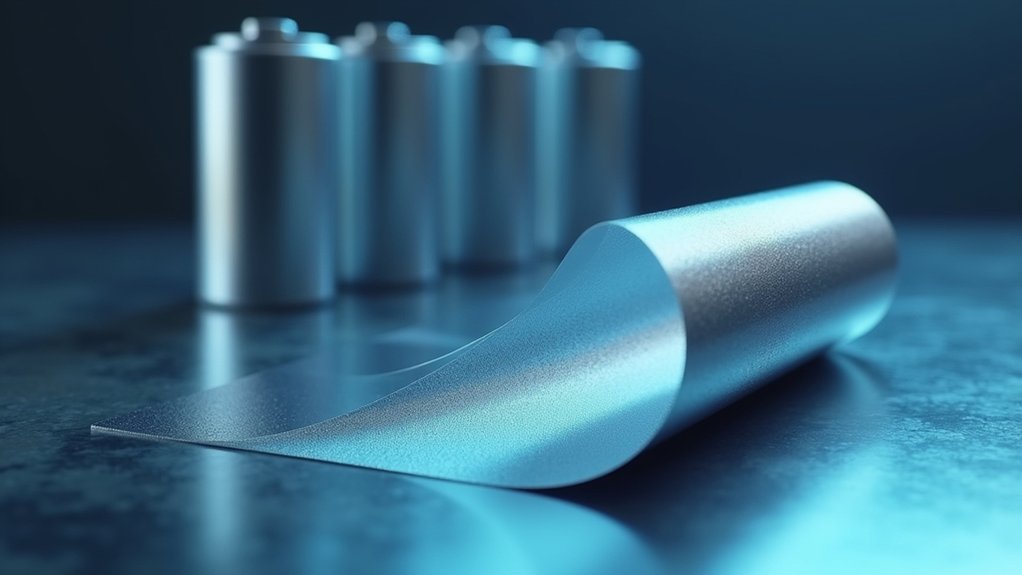

Engineers have shattered conventional battery design limitations with the development of ultra-thin lithium anodes, poised to revolutionize the electric vehicle industry. These remarkable components, measuring less than 50 μm thick—with some variants as thin as 6.5 μm—deliver an impressive 3,860 mAh g⁻¹ capacity, dwarfing traditional graphite anodes that max out at 372 mAh g⁻¹. The technological leap forward isn’t merely incremental; it’s transformative for the EV ecosystem.

Ultra-thin lithium anodes under 50 μm deliver 3,860 mAh g⁻¹, transforming EV batteries beyond incremental improvement.

The performance metrics are compelling. These ultra-thin anodes possess 10 times the energy capacity of conventional graphite counterparts, translating to a sevenfold increase in battery longevity. I’ve analyzed numerous battery technologies, and few innovations offer such dramatic improvements while simultaneously reducing material costs by up to 25% through minimized copper usage.

This cost efficiency, coupled with enhanced gravimetric and volumetric energy density, creates a perfect storm for next-generation power solutions. These advanced foils combine ultra-thin lithium with copper in a laminated structure designed specifically for pouch and cylindrical cells. Unlike conventional batteries, these innovations could potentially integrate into structural batteries that form part of the vehicle frame itself, further increasing efficiency.

Production challenges have historically limited commercial viability, especially concerning dendrite growth and SEI degradation. However, recent breakthroughs in electrolyte additives have dramatically improved stability profiles. The addition of silver trifluoromethanesulfonate (AgTFMS) has proven exceptional at forming both Ag and LiF simultaneously on the lithium surface, preventing dendrite formation.

Roll-to-roll PVD technology now enables scalable manufacturing with precise thickness control, a genuine game-changer for mass production economics.

Vehicle manufacturers stand to benefit enormously from these advancements. The reduced weight directly impacts EV range capabilities, while improved packing efficiency—reaching 90-95%—optimizes space utilization in tight chassis designs.

Products like Sion Power’s Licerion® anode, paired with nickel-rich cathodes, demonstrate how these technologies translate to real-world applications.

Safety concerns remain partially unresolved, particularly regarding dendrite formation under extreme charging conditions. Yet pilot-scale production facilities are validating mitigation strategies with promising results.

The shift to commercial production appears imminent, with early adopters likely to implement these anodes in premium EV models first. When fully deployed, these ultra-thin lithium anodes will finally deliver the holy grail of EV batteries: lighter, smaller power sources with dramatically extended lifecycle performance.